Individual

solutions for the

semiconductor industry

Semiconductor industry

The demand for semiconductors has continued for decades and is still growing rapidly. Driven by rapid development in digital manufacturing automation and the increasing demand for integrated circuits, chip manufacturing output continues to thrive. As a result chip manufacturers are producing larger and higher-purity wafers, which require the use of ever larger wafer furnaces and process chambers.

In addition to the supply of large-volume quartz tubes by Raesch Quarz (Germany), Raesch also supplies the semiconductor industry with various manufactured products. The high-purity quartz glass, together with Raesch's laser CNC machine, has proven to be a winning combination for supplying the semiconductor industry with quartz glass consumables.

Do you need

customised

quartz glass products?

Enquire now and we'll take care of the rest

Process Cylinders

In the semiconductor industry, annealing and diffusion are necessary manufacturing steps for wafer production. The steps take place in quartz glass reactors of horizontal or vertical furnaces. During the processes, silicon wafers are fed into a quartz cylinder and heated in a controlled manner. And the process cylinder must be precisely matched to the reaction chamber in the wafer furnace. To support this industry need, we manufacture high-purity resized tubes with customer-specific dimensions, thus guaranteeing the perfect solution for every wafer producer.

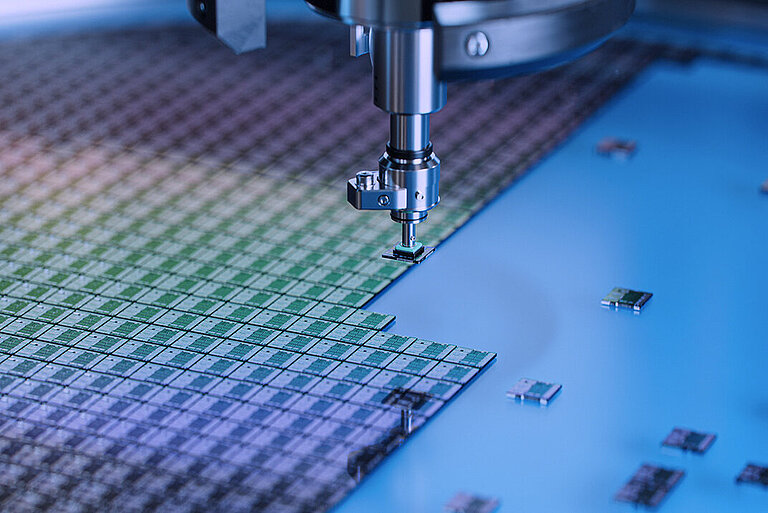

Quartz boats

To transport the wafers into a diffusion or oxidation furnace, wafer carriers “boats” are utilized. These boats place particularly high demands on the purity and temperature resistance of the quartz from which they are made. To fabricate the wafer boats, individual components such as spiders and pins made of quartz are required. And Raesch provides the quartz rods that are used in the fabrication of these components.

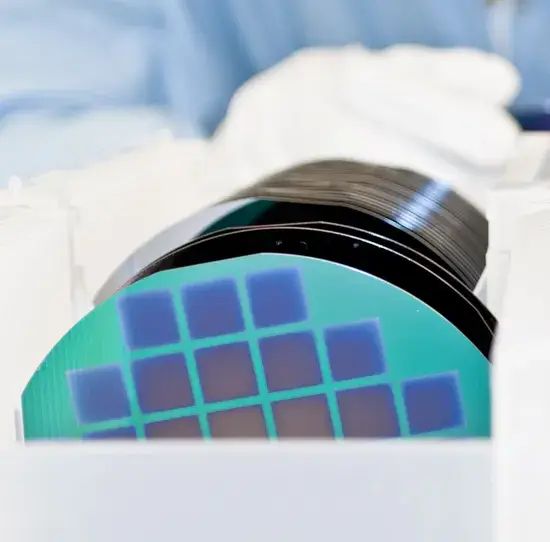

Quartz glass carrier

In the production and refinement of wafers, their purity is a top priority. This also applies to the production components which come into contact with the semiconductors during wafer production, such as the wafer carriers. As such, stacking systems made of quartz glass and other high purity materials are also required in ultra-clean rooms for the storage and transport of wafers.