Worldwide sales network

Fused quartz glass with a worldwide sales network of experienced sales partners

Resized

quartz glass

tubes

For demanding applications

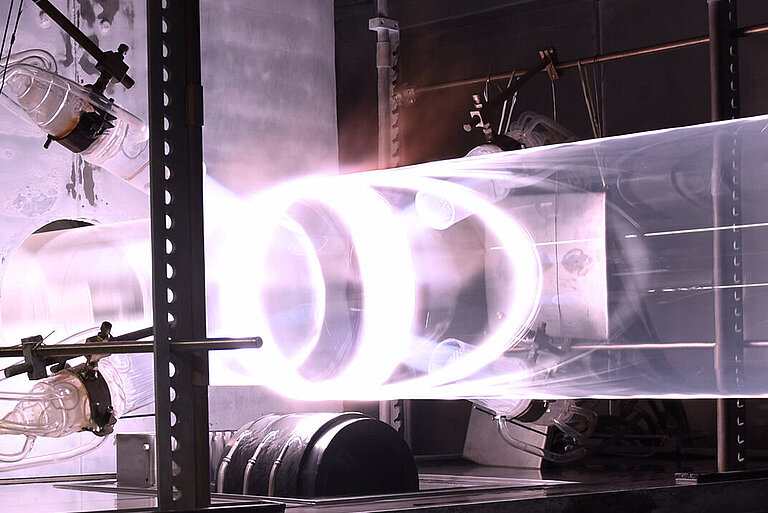

Raesch Quarz (Germany) operates its own resizing center for quartz glass tubes at its Langewiesen site. On high-performance and modern glass lathes, our highly qualified employees produce quartz glass tubes with outer diameters from 50 to 950 mm and wall thicknesses of up to 9 mm. Feedstock tubes in various quartz grades that were previously produced directly are further processed into resized (RSC) tubes via a specially developed two-stage process. In this rotational process, several gas flames heat the material over the entire surface, causing the quartz tube to deform in a controlled manner due to the centrifugal force. This enables us to achieve customer-specific dimensions in terms of outer diameter, length and wall thickness.

Make an inquiry now and we will take care of the rest

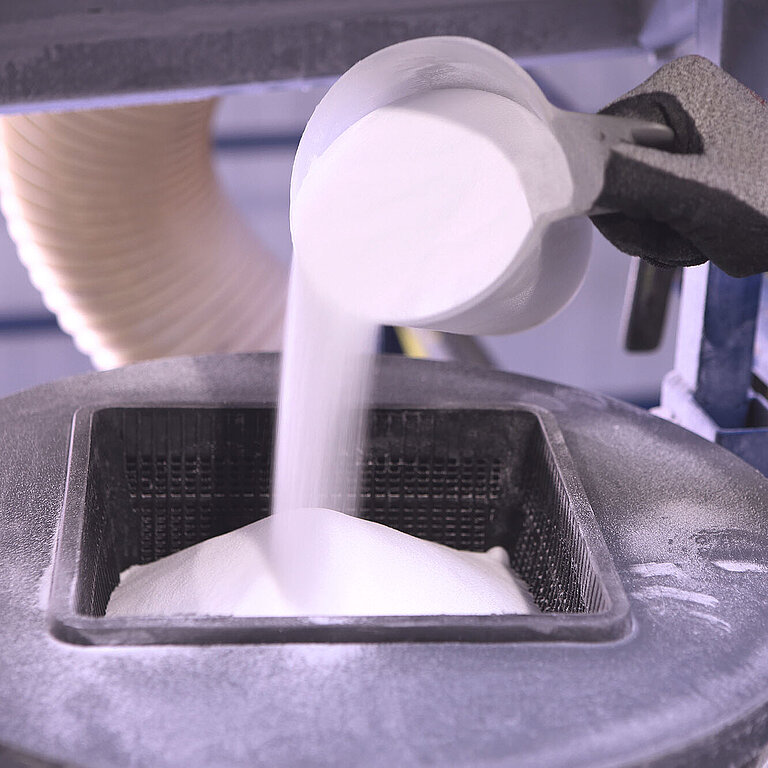

We produce quartz resized tubes using high-purity, quality-tested raw materials. Our production ensures consistently high material purity and dimensional accuracy. The resized tubes are available in the material grades RQ200, RQ235, RQ245, RQ500 and RQ800. Each grade differs in its physical and optical properties and is thus suitable for particular applications.

Raesch Quarz produces resized tubes with individual, customer-specific dimensions in terms of outer diameter, length and wall thickness. Only the highest-quality, US-sourced sand is utilized for these tubes. And as such, we can produce the highest quality feedstock tubes for our resizing process. Our resized tubes meet the highest standards in terms of dimensional accuracy and siding, from which our customers in numerous industries benefit.

Our resize quartz glass tubes are made of high-purity quartz glass and are characterized by their excellent optical and thermal properties. Due to their high purity, chemical resistance, and typical temperature resistance, such quartz tubes are used primarily in the semiconductor and solar industries. There, the tubes are used in vertical or horizontal furnaces as reaction chambers for wafer production. The suitability of our quartz glass as process tubes becomes clear when one considers the substantial quality requirements for diffusion or oxidation processes under high temperatures.

Feedstock tubes in various material qualities, previously produced by direct drawing, are further processed into RSC tubes using a specially developed two-stage process. In a rotating process, several gas flames heat the material across its entire surface, causing the quartz glass tube to undergo controlled deformation due to centrifugal force. This enables us to vary individual, customer-specific dimensions in terms of outer diameter, length, and wall thickness.

Quartz glass tubes offer high chemical resistance, extreme temperature resistance, and excellent light transmission in the UV and visible range. This makes them ideal for demanding industrial applications where conventional materials would fail.

Thanks to their high purity, chemical resistance and exceptional temperature resistance, Raesch quartz tubes are mainly used in the semiconductor and solar industries. We are your competent partner and leading quartz glass tubes supplier. Trust in our high-quality quartz glass tubes and tailor-made solutions, precisely tailored to your requirements.

Worldwide sales network

Fused quartz glass with a worldwide sales network of experienced sales partners

Competence

Competence in the areas of quartz glass production and refinement

High-quality raw materials

Use of US raw materials for the highest purity

Qualified personnel

Qualified personnel with application technology knowledge

Individual production

Flexible production and individual solutions guarantee maximum variance

Everything from a single source

Different material qualities for different applications

Talk to us - we'll help you find the right solution.