Worldwide sales network

Quartz glass melt with worldwide sales network of experienced sales partners

Customised

Tubes made from

quartz glass

For demanding applications

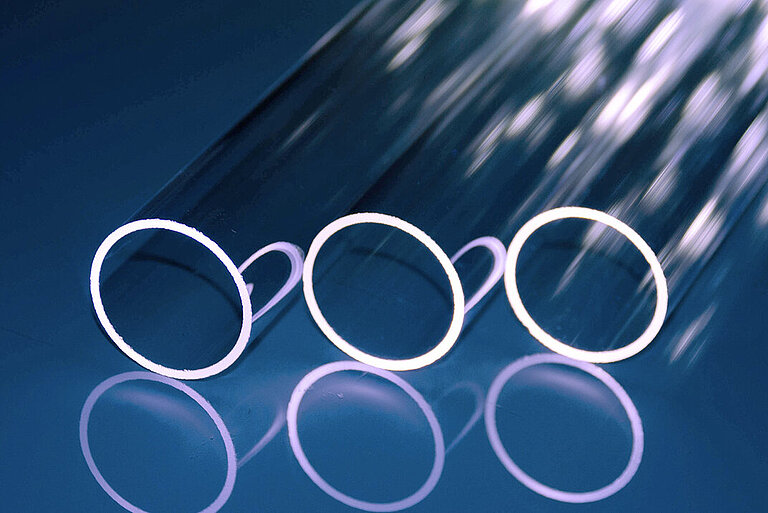

Raesch Quarz (Germany) GmbH is well known for its transparent and translucent quartz glass tubes. We develop, produce and sell high-quality quartz tubes for demanding process applications such as in the semiconductor industry. As an example, the tubes are perfectly suitable for process reactors due to their excellent temperature stability and purity. In the lamp industry, our quartz glass tubes are used as lamp bodies and protective tubes. And the chemical resistance of quartz tubes makes them an ideal reaction vessel for the treatment of aggressive acids and water.

Make an inquiry now and we will take care of the rest

We produce quartz glass tubes using high-purity, quality-tested raw materials. Our production process ensures consistent high purity and dimensional accuracy. The quartz glass tubes are available in a number of material grades: RQ200, RQ235, RQ245, RQ500, RQ600, RQ800 and Novosil. Each grade differs in its physical and optical properties and is thus suitable for particular applications.

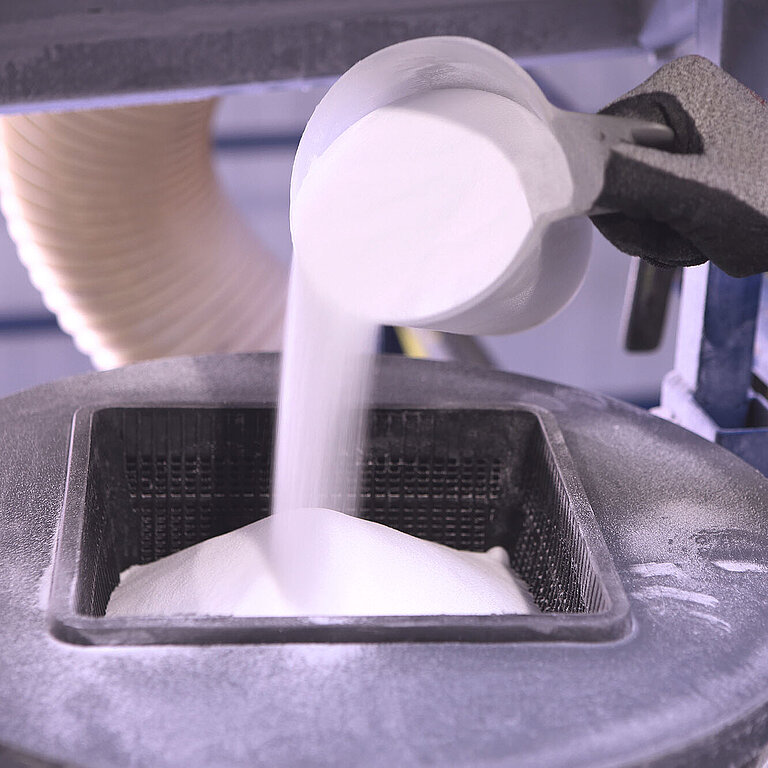

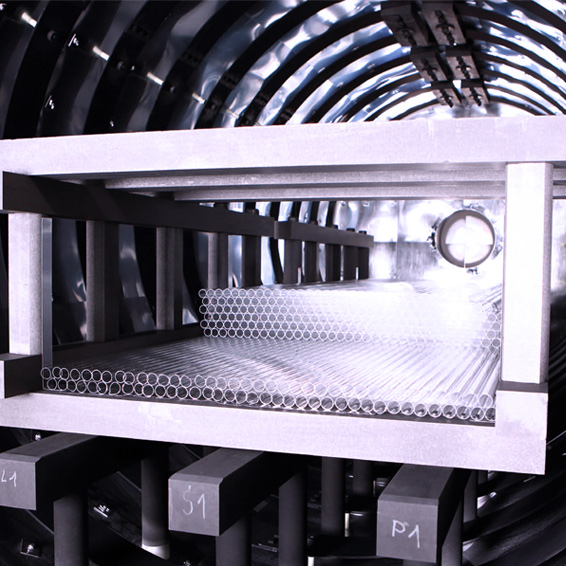

In the single-stage process (known as the drawing process), the quartz glass tubes are manufactured directly and without further processing steps. Our induction melting furnaces enable the production of quartz glass tubes with outer diameters ranging from 13 to 310 mm, and with variable wall thicknesses and lengths. We use only high-quality raw materials for the production of our quartz glass tubes.

Due to the single-stage drawing process, Raesch Quarz can produce quartz glass tubes with high precision and dimensional accuracy. And our flexible production process allows us to quickly effect material changes for specific customer requirements.

At the customer's request, we can provide additional finishing steps to our quartz glass tubes. With state-of-the-art cutting machines, we can trim (fine) cut tubes to the desired length before delivery. We also offer special cleaning processes and vacuum annealing to provide a residual OH content down to <1 ppm, which significantly improves UV transmission (and strength for high temperature handles). These finishing steps, as well as the option for quartz glass calibration , make us a preferred tube manufacturer for lamp, semiconductor, solar and chemical manufacturers worldwide.

Quartz glass tubes are made of high-purity quartz glass and are characterized by their excellent optical and thermal properties. They are used in the lamp, chemical, semiconductor, and solar industries, including as protective tubes, UV-transparent tubes, and in high-precision manufacturing processes.

Production takes place using the so-called single-step process, in which quartz glass is processed directly in melting furnaces. This enables the production of tubes with variable diameters, wall thicknesses, and lengths without any intermediate steps. Quality is ensured by the processing and doping of the quartz sand as well as by modern melting technologies.

Quartz glass tubes offer high chemical resistance, extreme temperature resistance, and excellent light transmission in the UV and visible range. This makes them ideal for demanding industrial applications where conventional materials would fail.

Yes, we offer customized solutions. This includes custom dimensions, special finishing processes such as cleaning, calibration, or annealing, as well as adaptations for specific applications in the lamp, chemical, or solar industries.

Whether your company is in the lamp, semiconductor, solar or chemical industry - Raesch Quarz can be your competent partner for quartz glass tubes. And you can trust our tubes, which are recognized for their high quality and are precisely tailored to your requirements.

Worldwide sales network

Quartz glass melt with worldwide sales network of experienced sales partners

Production competence

Expertise in the areas of quartz glass production and refinement

High quality raw materials

Exclusive use of US raw materials for the highest purity quartz (transparent products)

Application knowledge

Qualified personnel with in-depth knowledge of typical applications

Flexible production process

Products tailored to specific customer requirements

Single source supplier

Various quartz grades for particular applications

Fused quartz, a type of quartz glass, is characterized by its simple chemical composition which consists almost exclusively of silicon and oxygen (silicon dioxide). In contrast to conventional glass, it does not contain any dopants such as soda or calcium oxide. Notable advantages of fused quartz include its exceptionally high temperature and thermal shock resistance, and its extremely low level of impurities. Owing to fused quartz’ outstanding physical and chemical properties, this special glass is particularly suitable for applications with stringent requirements.

Talk to us - we'll help you find the right solution.